Kenaf Wood Industry

The kenaf wood industry has the potential to replace many wood resources and probably should. Let's take a good look at some of the key elements.

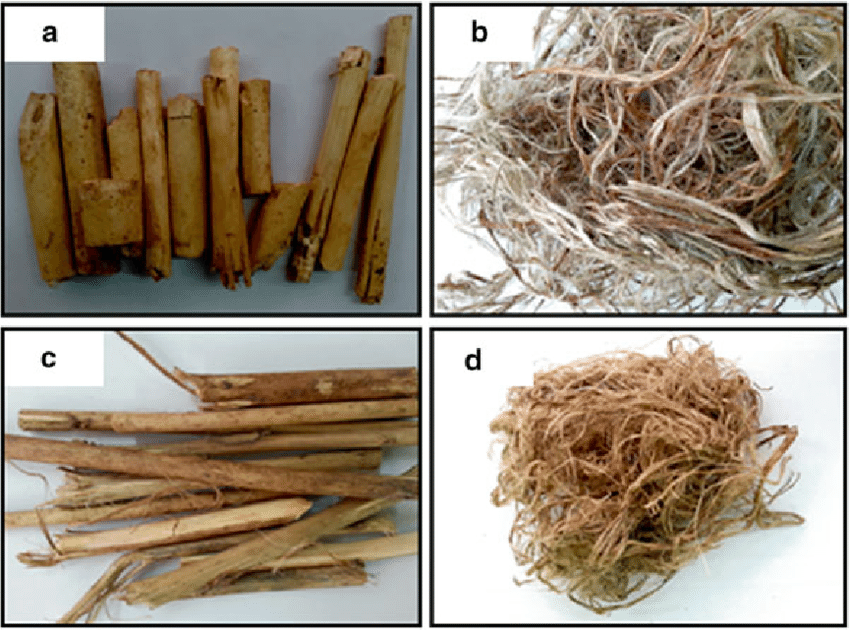

a and c Kenaf Wood Core b and d Kenaf Fiber

Hemp Wood Uses Video

Here is a video showing some of the fiber, wood and seed products made in the USA from industrial hemp. These same products can be made from kenaf. Video of products made in the US by Derek Cross. Watch the video.

Kenaf Wood Industry

vs

Forest Wood Industry

If one acre of kenaf produces 4-5 times more wood material than trees as some have claimed, shouldn't we be looking into the kenaf wood industry instead? Can we do this in a practical and viable way? Does it make sense to introduce this to the logging companies and help them transition to this renewable source for their customers? Most of us would say yes to these 3 questions but what would it take and how would we go about it?

Fifty plus years ago, as a teenager, my parents would load my brothers and sisters and I up in the family station wagon and head to northern Michigan for a 2 week summer vacation. I remember the long roads with tree branches from either side touching each other. Giant pine trees reaching 200 feet towards the sky. Logging trucks filled to the max with the wood from one tree. A walk in the woods where multiple species of hardwoods and pines too large to wrap your arms around, accompanied by the distict smell of soil in the making. I fell in love with the north country and retired here in 2015. This is what we should be seeing in our forests, both young and old trees. Mixed hardwood and pine.

Today on a regular basis I see logging trucks filled with logs harvested from many trees and some I can wrap my 2 hands around.

Lets' protect these valuable forests and look for other ways to meet our needs.

Having logged in New York state 1982-1983. Harvesting just a few trees in a section of forest leaving most of the old growth forest in tack. One 200 foot pine could fill a truck.

Logging sites as I have seen from the road these days are void of most trees, leaving a few Poplar Trees to fill in the empty space over the next 20-40 years.

White poplar was first introduced to North America in 1748 and has a long history in cultivation. It is now found in 43 states throughout the contiguous U.S. It has come to be considered weedy or invasive;

Common Uses: Seldom used for its appearance, (except in the case of Rainbow Poplar), Poplar is a utility wood in nearly every sense. It's used for pallets, crates, upholstered furniture frames, paper (pulpwood), and plywood.

I continue to get excited when I find something new going on locally where kenaf wood material could be used in existing industries and replace current insustainable practices. Here in northern Michigan we have lots of trees being harvested and used locally. Some I have discovered so far include - pellets made from trees(we heat with these), particle board manufacturing (4 million board feet per year), pallets and toilet paper.

We also have thousands of acres of corn, and soy fields that could benefit from growing kenaf on a rotational basis as a cash crop. Some of the fields have been abandoned for a year or more.

Kenaf Wood Industry

Current and Future Uses

Here are some of the uses in the kenaf wood industry:

- Horse bedding the best absorbent bedding is kenaf

- Particle Board (Japan claims it is the superior resources for this)

- Oil spills for land and water

- Erosion control on steep sides of highways

- Housing made of kenaf wood core called kenafcrete Eco-Friendly Housing

- Paper Products Paper products

- Growing medium for hydroponic and aquaculture growing operations

- Flooring

- Feed stock for 3D printing

- Photovoltaic nano sheets i.e. solar energy

- High capacity storage batteries

And More!!!

Erosion Mats for Highways.

Kenaf Wood Industry

Benefits

When you look at the kenaf wood industry as a single industry for this remarkable plant along with the benefits, it warrants serious consideration. When you look at multiple industries from a single plant it gets more interesting. Putting the icing on the cake are some benefits that may be considered vital in these times.

- Kenaf removes more carbon from our atmosphere that any other plant. It does this while it is growing and after it has been harvested i.e. kenafcrete.

- It is known to remove toxins in the soil including heavy metals.

- Does not require fertilizer

- Improves soil condition by handling harmful organisms

- Drought tolerant.

- Requires little or no weed control

- Does not require pesticides

You could grow kenaf for the wood industry, fiber industry and seed industry at the same time.