Kenaf Fiber Industry

Country Song

The kenaf fiber industry is blossoming into a network across the globe. As new partners come on board we have found that it could not be contained in the U.S. alone.

Each new partner brought something new and exciting to the list of possibilities in new and existing businesses. With influencial connections and partners discovering kenaf for the first time, the demands continue to grow and we expect this to go on well into the future.

There is plenty of opportunity for others to join in and be at the forefront of this global movement.

Kenaf Fiber Powder

We now have a partner in Michigan that can take our kenaf stalks and seeds and then turn them into powder with less than 1% moisture and in various particle sizes as small as cosmetic grade.The above photo is powder made from industrial hemp stalks at this processing center. The advanced technology being used can take wet or dry stalks moldy or not moldy and select particle size and process it to your specifications. All mold, bacteria and toxins are removed during processing.

Seed powders/flour can be used in recipes for food and fodder. Fiber powder can be used in bio-plastic feed stock and paper products.

Kenaf Fiber

Kenaf fiber is an ideal for the Fiber Industry. Kenaf fiber can and is being used in industries looking for a sustainable and superior fiber for various applications. To meet the increasing demands for quality fiber at prices and quantities manufacturers are looking for, we partner with our farmers/suppliers to accommodate the needs of processors and manufacturers. Restrictions of industrial hemp in whole countries and states within the US, makes kenaf the alternative choice. We now have 20 partners in 11 countries with our kenaf seed.

Whether it is kenaf stalks, short or long kenaf-fiber, coarse or fine kenaf fiber we partner with those that can meet your requests.

Separating the bark/fiber strands from the inner wood core is a process called "decortication". Specialized equipment for this processing method is needed to service textile industries, specialized filters in waste management, growing mats, erosion control mats, insulation bats, fabric and fabric blends, bio-plastics, paper and packaging (25,000 + uses) supplying existing and new industries to name a few.

During the decortication process the wood core is separated from the fiber and sized to programmed specifications up to 2 inches. The wood core/chips are being used in specialized industries i.e. kenafcrete home building, wood pellets for wood stoves, particle board manufacturing, wood mulch for rejuvenating citrus fields and making biocharand more.

Biochar is needed for water filtration, waste management sludge, and soil improvements.

Our Fine Kenaf Fiber

Our Medium Kenaf Fiber

Our Long Kenaf Fiber

Here is a video showing some of the fiber, wood and seed products made in the USA from industrial hemp. These same products can be made from kenaf. Video of products made in the US byour partner Derek Cross. Watch the video. Combining the best of industrial hemp and kenaf with fiber processing centers makes for a great partnership. Some of our partners grow both industrial hemp and kenaf.

Kenaf Fiber Industry

Processing

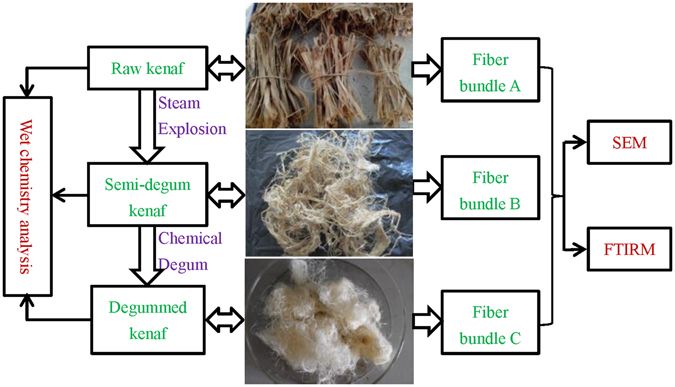

The above diagram shows one form of processing fibers. There are bacteria methods, chemical methods and mechanical methods of separating the fiber from the core. Our mechanical processing equipment is the best in the world for fiber and wood core processing.

Once the kenaf stalks are harvested and the outer fiber is separated they go through a refinement or combing process making the fiber finer and finer. Course fiber for burlap quality products to very fine fiber for linen or silk or cotton blends.

Partners Wanted in the Kenaf Fiber Industry

One of our partners has 200 MT of fiber for sale at $771.75/MT plus shipping and handling.

Also 200 MT of core for $595.35/MT - $1,874.25/MT depending on quality. Shipping and handling is extra.

Whether you have fiber to sell or looking to purchase fiber let us know what you are interested in. We'll do our best to meet your needs and wants. Send your request to:

bob@kenafpartnersusa.com